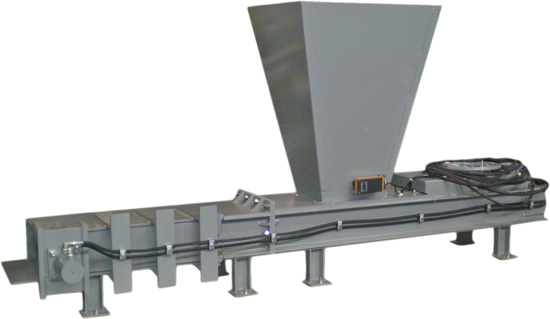

Managing expanded polystyrene (EPS) foam waste efficiently is a growing priority for many industries. EPS foam densifiers, like the Toronita series offered by Precision Machinery Systems, provide a powerful solution for compressing bulky foam into dense, manageable blocks, reducing waste volume by up to 50:1. This process helps businesses save money on transportation, improve recycling processes, and minimize their environmental impact. Here are the top five industries that benefit most from using EPS foam densifiers.

Managing expanded polystyrene (EPS) foam waste efficiently is a growing priority for many industries. EPS foam densifiers, like the Toronita series offered by Precision Machinery Systems, provide a powerful solution for compressing bulky foam into dense, manageable blocks, reducing waste volume by up to 50:1. This process helps businesses save money on transportation, improve recycling processes, and minimize their environmental impact. Here are the top five industries that benefit most from using EPS foam densifiers.

1. Packaging and Shipping Industries

The packaging and shipping sectors generate substantial amounts of EPS foam waste due to protective materials used for fragile items. EPS foam densifiers allow these industries to compact foam waste into dense blocks, significantly reducing the space needed for storage and the frequency of waste pickups. By lowering transportation costs and making foam recycling more efficient, densifiers also help these industries meet sustainability goals.

2. Retail and Wholesale Businesses

Retailers and wholesalers dealing with large shipments often face challenges in managing EPS foam waste from product packaging. A densifier transforms this bulky waste into compact blocks, freeing up valuable storage space and making it easier to handle waste removal. Additionally, recycling the compressed foam can generate revenue, making densifiers an excellent investment for businesses looking to offset waste management costs.

3. Construction and Renovation Companies

Construction and renovation projects frequently involve EPS foam for insulation, structural support, and soundproofing. These materials often result in significant waste. By using an EPS foam densifier, construction companies can efficiently manage foam waste on-site, reducing disposal costs and aligning with green building practices. Recycling densified foam also demonstrates a commitment to sustainability, which is increasingly important in the industry.

4. Food and Beverage Industries

EPS foam is commonly used in the food and beverage sector for items like takeout containers, trays, and coolers. With increasing regulations around waste management and sustainability, these businesses can use densifiers to streamline the disposal and recycling of foam materials. Compacting foam waste not only helps these businesses comply with regulations but also reduces their environmental footprint.

5. Manufacturing and Industrial Operations

Manufacturers using EPS foam in production or packaging processes generate large quantities of waste. EPS foam densifiers help streamline waste management by reducing the volume of waste generated and simplifying recycling logistics. By densifying foam on-site, manufacturers can lower their transportation costs and create a cleaner, more organized workspace.

Why Invest in an EPS Foam Densifier?

EPS foam densifiers provide a cost-effective, environmentally friendly solution to manage foam waste. Industries that adopt this technology benefit from reduced waste disposal costs, increased recycling efficiency, and a greener operational footprint. Precision Machinery Systems offers a range of EPS foam densifiers, including models with varying capacities to suit businesses of all sizes.

If your business generates EPS foam waste, consider investing in a densifier to transform your waste management strategy.