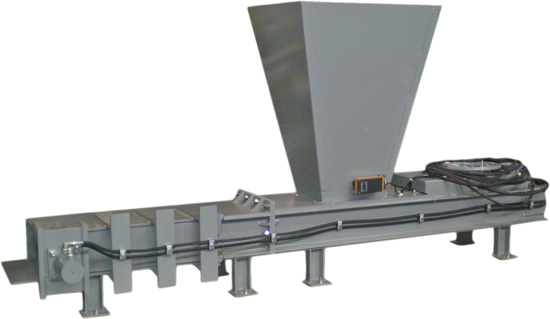

TORONITA EPS FOAM DENSIFIERS MODEL 60XP

The Toronita Model 60XP EPS Foam Densifier is a horizontal machine which produces a continuous ribbon of densified material. The densified ribbon can easily be broken into manageable segments for handling and stacking. Densification takes place in the snout of the machine due to pressure applied by a side control cylinder.

The Toronita Model 60XP EPS Foam Densifier is a horizontal machine which produces a continuous ribbon of densified material. The densified ribbon can easily be broken into manageable segments for handling and stacking. Densification takes place in the snout of the machine due to pressure applied by a side control cylinder.

Operation is automatic, with the unit being activated by an electric eye which senses material in the loading hopper. Optional material prebreaker, air conveyor and storage bag over densifier hopper provide an efficient system for densifying large volumes of expanded polystyrene. This model is equipped with a power feed section on the hopper which provides a higher throughput without moving up to the next larger machine.

The output capacity for expanded polystyrene material is up to 400 lbs. per hour, vs. up to 200 lbs. for a standard Model 60X. The machine is equipped with a 15 HP motor operating at 230 or 460 volts, with a 180 gallon reservoir.

SPECIFICATIONS

- Output Capacity: Up to 400 lbs/hr

- Electrical: 208 / 230 / 460 / 3 Phase, 60 Hertz

- Cycle Time: 60 Seconds

- Hopper Volume: 20 cf

- Hydraulic Reservoir Capacity: 180 Gallons

- Overall Dimensions (L x W x H): 192 ¾ x 39 x 58 in

- Weight: 5,600 lbs

- Densified Ribbon Size: 20 x 10 in

- Motor Horsepower: 15

RECOMMENDED INDUSTRIES

- Auto Industry

- Foam Manufacturing Facilities

- Recycling Facilities

- Other Manufacturing Operations