Efficient waste management is critical for maintaining clean and organized facilities, especially in multi-story buildings, commercial spaces, and industrial operations. When selecting a trash compactor, understanding the differences between vertical and horizontal models is essential to making the right choice for your building’s specific needs. In this guide, we’ll break down the key differences, highlighting the features of the AUTO-PAK Vertical DD30 Series and the Horizontal Gobbler Series to help you make an informed decision.

Efficient waste management is critical for maintaining clean and organized facilities, especially in multi-story buildings, commercial spaces, and industrial operations. When selecting a trash compactor, understanding the differences between vertical and horizontal models is essential to making the right choice for your building’s specific needs. In this guide, we’ll break down the key differences, highlighting the features of the AUTO-PAK Vertical DD30 Series and the Horizontal Gobbler Series to help you make an informed decision.

1. Space Requirements: Optimizing Your Building Layout

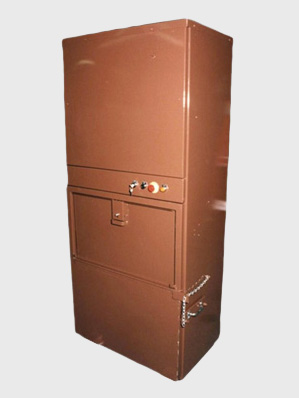

One of the most important factors when choosing between vertical and horizontal trash compactors is space availability. Vertical compactors, such as the AUTO-PAK DD30 Series, are designed to take up minimal floor space, making them ideal for facilities with limited room. These compactors are typically installed in tight spaces and are often hand-fed, though they can also be adapted for use with trash chute systems.

On the other hand, horizontal trash compactors, like the Gobbler Series, require more floor space but offer increased waste handling capacity. These compactors are perfect for below-grade trash rooms in high-rise buildings, where space is less of a constraint and large volumes of trash need to be compacted regularly.

2. Waste Volume: Matching the Compactor to Your Needs

The volume of waste generated by your building is another crucial consideration. Vertical compactors are better suited for moderate waste volumes, such as those found in smaller apartment buildings, retail stores, or offices. The DD30 Series, for example, can compact trash into 6.84 cubic foot bags, handling up to 200 pounds of compacted waste per cycle.

For higher waste volumes, horizontal compactors are the superior choice. The Gobbler Series, with models designed to handle large-scale operations, can compact trash into multiple bags or containers, making it ideal for facilities like high-rise apartments, hotels, or large commercial complexes.

3. Ease of Use and Maintenance

Both vertical and horizontal compactors offer features designed for user convenience and safety. Vertical compactors like the DD30 Series include adjustable ram strokes and safety interlocks on loading doors, ensuring easy operation and secure handling. These compactors are typically easier to install and maintain due to their compact design.

Horizontal compactors, such as those in the Gobbler Series, often feature automatic operation triggered by an electric eye. This automation makes them well-suited for high-traffic environments where continuous waste management is needed. Although they require more space, their higher capacity can reduce the frequency of bag changes and waste pickups, saving time and labor costs.

4. Environmental Impact and Cost Efficiency

Both vertical and horizontal compactors are designed to reduce waste volume, cutting down on transportation costs and landfill use. Horizontal compactors excel in sustainability for facilities generating large waste volumes, as their multiple-bag systems reduce pickups and emissions associated with waste hauling. Vertical compactors, meanwhile, are cost-effective for smaller operations, offering a budget-friendly solution with less upfront investment.

Choosing between vertical and horizontal trash compactors depends on your building’s specific needs, including space availability, waste volume, and operational goals. For buildings with limited room, the AUTO-PAK DD30 Series is an excellent choice, while the Gobbler Series horizontal compactors are ideal for handling large-scale waste efficiently. Explore the full range of trash compactors available at Precision Machinery Systems to find the perfect solution for your facility’s waste management challenges.